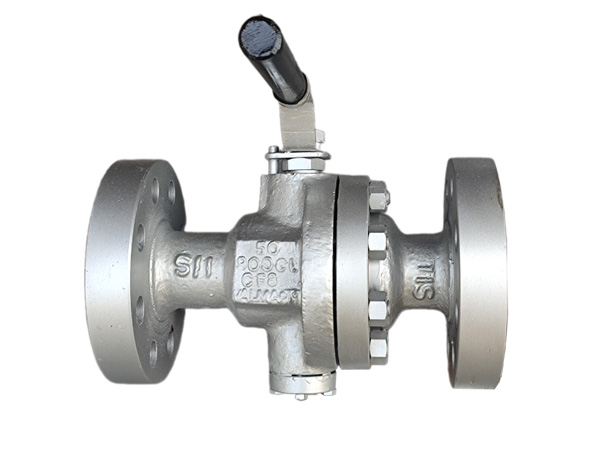

A floating ball valve having a ball inside the middle of the valve.

This ball is guided with the stem and treat as floating in motion. This is the reason it is called floating ball valve.

There are three designs as below:

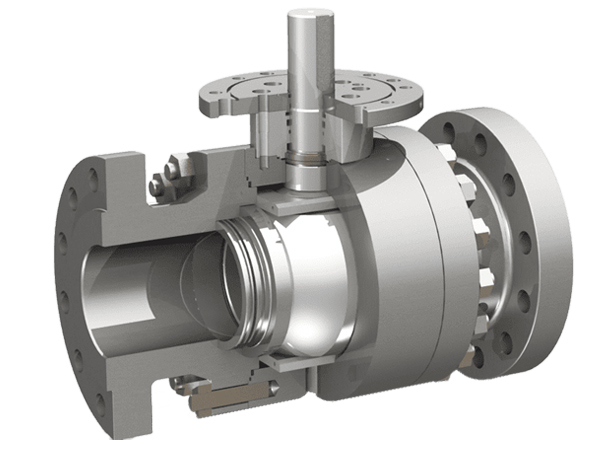

The trunnion ball valve is used as a controller of fluid, steam, gas or oil in the pipeline. It regulates the fluid flow. It is a quarter-turn valve with a ball. The ball situated inside the centre of the valve. It is rotate 90 degrees on its axis. It is used to stop or start the flow of fluid. The spherical hole in solid or hollow ball, which rotates to regulate the start-stop flow cycle.

The bottom shaft holds the ball and allow a smooth movement in a controlled manner which are mechanically

supported.

In this way the flow is regulated and valve operated easily even high pressure.

Due to this efficiency, a Trunnion mounted ball valves are used in industries where to rheostat such shut-off operation and high pressure are required.

The Double Block and Bleed valve or DBB valves are. It is made up of two ordinary ball valves linked by a common inlet end. The double block and bleed ball valve substitute several connections between conventional valves. As the name suggests, it is a double block and bleed ball valve used to double controller for the fluid system. The characteristic between this DBB valve and the conventional one is that it is effectively useful to shut the leakage that happens during system operation, and it can be quickly closed and can discharge easily. The DBB ball valve is widely used in the typical gas & oil application.

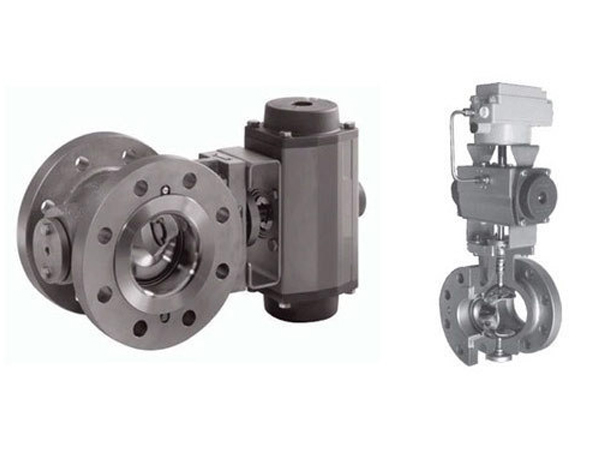

A segmented ball valve is a type of ball valve with a V-notch or V-Port segment inside the ball. Segmented ball valves are used in such application where need to control valves that have good control, rangeability, and shut off capability. This valve is able to producing high capacity and non-clogging flow control. V-Port ball valve is having the design of the ball with special machined bore to enhance capacity and shutoff integrity and seal life. V-Notch ball valves are known to be cost-effective and of high efficiency. These valves can be of a wide range such as small and lightweight valves or large heavy-weight valves. The lightweight valves are easy to mount, handle and transportation. The heavy-weight segmented ball valves are used in corrosion process to deliver best control and for on/off or modulating applications. Due to these characteristics, V-Port ball valves are used in variety of industries such as paper and pulp industries, refinery, and petrochemical services among others. These valves are sturdy and reliable even when used in tough environments.

The Ball Valves are used as automatic valve controller. These valves can be operated by an electrically controlled motor, a pneumatic device, or a hydraulic device. The selection of such operators is depended upon system's requirements. There are many designs available in respect of operator and this design has their own advantages and disadvantages that depends upon requested fluid application. These automatic actuators provide manual operations at a time of emergency. There are physical & virtual position indicators available.

The ball valve normally comes with two-way flow i.e., two port, inlet & outlet. Some applications required multi-port connection. To full fill this requirement, 3-way or 4-way ball valves may be recommended. In three-way ball valve, the main flow or inlet flow divided into two-way directions. It will be used in mixing or diverting applications. In the same way 4-way valves used in critical process industries.

Forged ball valves are used under high pressure line. The sizes of forged ball valves are small from 15mm to 50mm. It comes with socket weld, butt weld and threaded connections.

Forged steel ball valves are available in full bore and reduce bore. These valves come with the simple structure, small size, and reliable in nature. It has two sealing area and the various kinds of plastics are now widely used for the sealing for the tight shut off. It was widely used in vacuum systems. The forged ball valves are easy to operate, open and close quickly, only needs to rotate 90 degrees from fully open to fully closed able to operate by remote control and automated by another automatic operator. The forged steel ball valves are simple in structure, sealing ring is generally active, removal and replacement are more convenient. The sealing surface of the ball and valve seat is isolated at full opening or full closing from the medium, and when the fluid passes, it will not cause the erosion of the valve sealing surface. The forged ball valve is wipeable during the running process, it can be used in a medium with suspended solid particles.

These valves come in three-piece or two-piece body assembly usually. The side entry ball valve is a valve in which a ball is assembled from the side. Each piece is assembled by use of a stud or bolt similar to joining two pieces. These valves are produced from forge or cast metal. Each part of the body is investment casted. These valves are fast assembled at the assembly line. Side entry ball valves are widely used. A side entry ball valves are designed to improve high performance and it has a vigorous design as per international standards. Side entry ball valves have metal, soft or composite seats which can be arranged with either double or single piston effect to improve double block and bleed in both closed and open situations. Side entry ball valves are made the valves with forgings and casting independent bellows or springs loaded floating seats that are always kept in contact with the ball. The sector where these valves are used as cryogenic, low emission, high temperatures, crude oil, natural gas, transmission lines, transmission pipelines, measuring stations, compression, reinjection, and pumping units among others.

PFA (Perfluoroalkyl vinyl ether resin) is inherently provided with thermal stability, chemical resistance and good mechanical properties, which are equal to or even better than those of PTFE, while it has overcome PTFE's difficulty with thermoplasticity.

An Electric Ball Valve is an automatic form of quarter-turn valve that uses gear trains and motors to switch flow. The gear train and motor system will open the valve when the ball's hole is in line with fluid flow. It will also automatically close when pivoted at 90 degrees by the manual override of the electric actuators.