A swing check valve prevent the flow back in the pipeline. When the pressure become zero the flap disc closes the orifice flow-port and back-flow is prevented by the swing check valve.It is a automated valve which is controlled by fluid pressure. The swing check valves allow one-way direction flow only.There is very low pressure drop and turbulence.

Installation of this type of valve must be horizontally. If there is installation of vertically, one should care the disc must be activated by fluid pressure up side and when pressure is zero, it will be closed by gravity pressure.

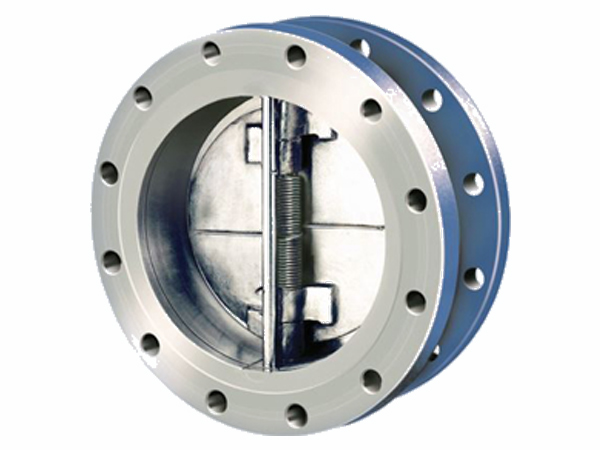

The Dual Plate Check Valves are mechanical valves which allow one way flow only. As name suggests there are two platesmechanically fitted with the spring. This spring activated with the fluid pressure and when the line pressure become zero, the valve is closed by spring.The main feature of the check valve is to secure the pipe line and other costly instruments from the back pressure.It is a one of an economic check valve with the higher slamming effect.Due to low slamming effect, it is very popular from plenty of the process industries.It is more economical than swing check valves.

A high-pressure check valves are used for above 500PSIG line pressure, who stop the reverse fluid flow.It is widely used after pumps. Whenever the sudden power switched off, the reverse pressure is generated, to stop this surge.This type of high-pressure check valves is used.These valves prevent the damage due to sudden surge pressure. The high-pressure check valves are used with boilers and pumps.The high-pressure check valves are made for critical & high-pressure levels application.The high tensile strength of this valve prevents to collapse at the time of leakage.High-pressure check valves are manufactured with the strong materials such as stainless steel, ductile iron, carbon steel, and cast iron among others as per application demand.

The non-slam check valves are self-acting valves. It is controlled by fluid pressure. There is very low noise in the opening and closing. It is also called nozzle check valves.The main functions of this check valve are to prevent the back flow. It is generally used for low pressure application.The non-slam check valves are used where the back pressure is increased above the system pressure.The non-slam check valves are used in low pressure pipe-line for one way flow.The seat is located for back pressure side in this self-operated check valves. This check valves are not recommended for the high viscus & Mart Valves media.

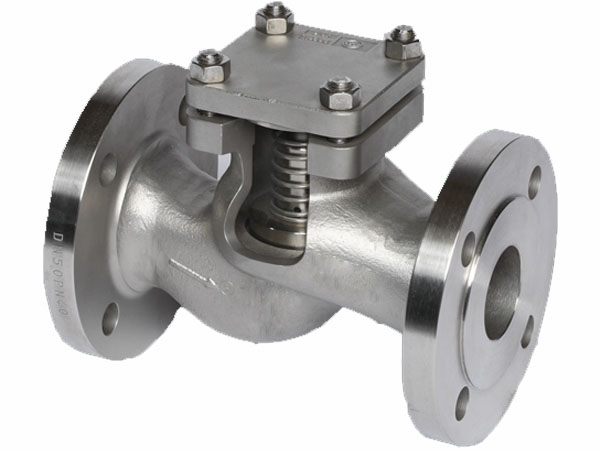

For high pressure non-return valve, piston type check is used. A piston check valve is used to prevent reverse fluid flow. It is mechanically fitted with the spring. The spring use the reverse flow pressure to shut the valve. The seat is situated in reverse side of all the check valve. The fluid flow is allowed only one direction only. It can be used with a dash-pot that consists of a cylinder and a piston for providing cushioning effect when the valve is operating. The guides help a proper alignment of the disc and seat at the time of piston closing. The fluid passes through the valve orifice area below disc.