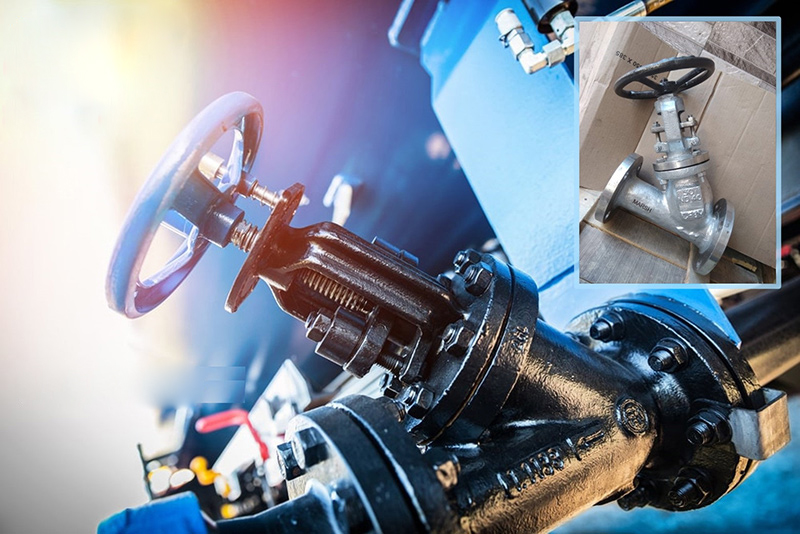

The disc of globe valves moves along the centreline of the seat. These valves generally used for the modulating to flow. This is happened because of change of the stroke of valve flap proportional to seat port. Due to small change of stem stroke, it shows smooth control that is the reason globe valve widely used to regulate the flow. Thus, the globe valve is more suitable for shutting-off or regulating and throttling.

The globe valve allows tight shut-off and smooth regulating of the flow. There is a torque applied via stem on valve seat area. This torque varies as per required flow so the valve used for application where flow regulating or zero leakage required.It is easy in manufacturing, assembly and maintenance.

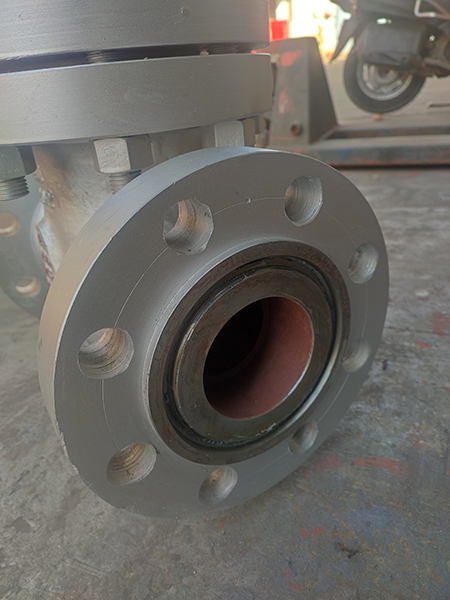

The stem extends toward the end of the disk from the bonnet in the high-pressure globe valve. In this operation condition a sealing ring parallel to the shape of the gap is provided in the annular gap formed between the cone of the inverted cone on the stuffing box, the inner hole of the valve body and the bonnet face the end face of the high-pressure globe valve. In this mechanism the use of the pressure of the liquid medium itself to achieve the purpose of sealing, the greater the pressure, the larger the sealing force, the more reliable the sealing, making it a pressure seal globe valve.The sealing performance is very good under high pressure and temperature condition even if fluctuation is noted. Compared with the forced sealing, it does not require a large bolt preload.

To handle the hazardous fluids, the industries use a Bellows sealed Valve. It is a specially designed valve suitable for use such industries. The bellows sealed valves does not allow any leakage. In the era of chemical and nuclear industries, there are extremely poisonous and toxic media flowing through the pipeline. It may cause very high loss of money and casualty of life. So, the pressure sealed valves are used in such pipes and systems have specific stringent leakage and sealing requirements.The bellow seal globe valves are the necessities of a completely different & desired sealing.

The pipe line is not always straight in the factories. Sometimes it is right angle 90° turn. However, it is handled by using Elbow but sometimes there are not much space to install elbow and valve. In this situation we use Angle Globe valves. This is the modified form of globe valve. The inlet and outlet in these valves are perpendicular to each other. If the pipe construction or pressure drop is much complex then we are using these types of Angle Globe Valves.

The name suggests, it is a type of check valve having design globe. It does not allow flow to back. The disc of the Globe check valve controls the flow of fluid. While the fluid return back the same disc closes the port area with the help of back pressure. In thus way it works automatically one way only. So, there is no cost of human to operate this. Globe check valves are using for many applications such as cooling and heating systems, boiler, and water systems among others. In the boiler application this valve shows very vital role to stop the steam backflow automatically. It ensures the safety of pipeline & pump due to over back pressure.

In Mixing application three-way globe valve is used for combine two streams of fluid that flow to a common outlet port. In mixing application, there is combining two different liquids to create a specific outlet product.

The common steam and splitting it into two outlet ports. It is generally used to switch a stream of fluid from one vessel to another vessel. It is also using in the control of temperature in a heat exchanger. The three-way globe valve directs one portion of fluid flow via the exchanger and the balance of the fluid flow bypasses the other exchanger.