A diaphragm valve is lined its body with rubber and diaphragm material is made of rubber suitable for fluid.This valve widely used in pharma sector, sewage treatment, paper processing, mining minerals, power generation stations,steelworks, and chemical industries. The body of diaphragm valve generally lined with hard and thick rubber. Due to this the fluid does not directly touch with the surface of valve body. The closing parts i.e., diaphragm is made of hard rubber to whole valve safe when handling abrasive and corrosive media. Thus, whole wetted component is protected by the rubber lining preventing hydro abrasion and corrosion.

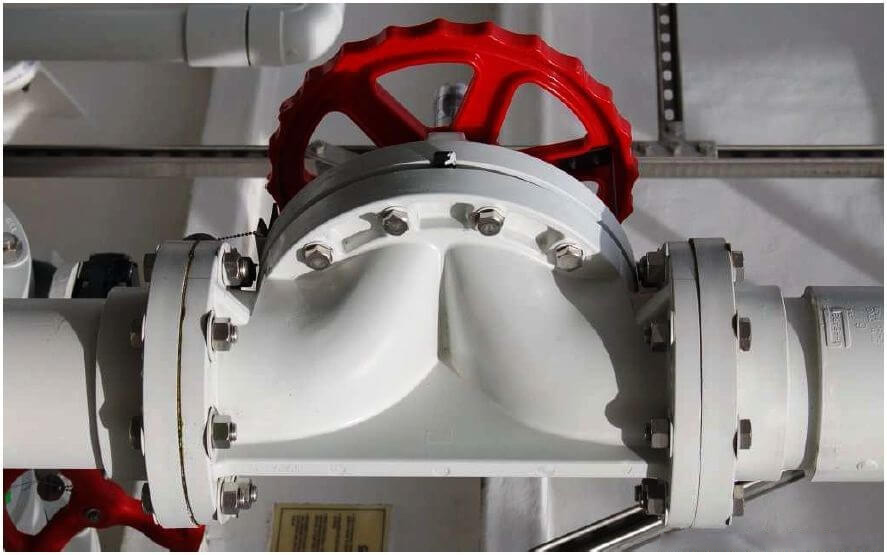

The Weir type diaphragm valve is a one type of valve under diaphragm valves. It very popular and demanding from various industries.In the weir type diaphragm valve, an elevated saddleback moves to close the port and lined material works as a tight sealing. This elevated saddleback reduces the travel from fully open/close position. Due to elevated diaphragm, the stress decrease in closing. The material of diaphragm is strong suitable for hight pressure and vacuum applications. It works a good control of fluid flow, modulating service with microscopic flow rates. There is two-piece compressor allow a small opening from the centre of the valve.Weir type diaphragm valves are frequently used to handle equal concentration and clean liquids and gases since contamination and viscous sludge can accrue on the saddle. The weir type diaphragm valves are also used on hazardous, rough, and harsh media.Weir type diaphragm valve has a flexible diaphragm which is connected to the compressor. The compressor is connected to the stem. The hand wheel guided with the stem is used to open & close i.e., to increase or decrease the flow rate.

Pneumatic diaphragm valves are used to control the flow of pungent gases, liquids, viscous media, colloids, sludge, corrosive water and slurries. It is controlled by pneumatic actuator. It is controlled by PLC via pneumatic accessories i.e., pneumatic positioners, limit switch. These valves are used in many applications such as pharmaceuticals, food processing, sewage pipelines, water treatment, pulp, and paper production etc.It uses a flexible diaphragm to control, hinder, or isolate fluid flow. Generally, these valves come with manufacturers standard. The sealing action of a pneumatic diaphragm valve is produced when a diaphragm is pushed on a solid weir in the valve body. Due to linear motion these valves are called linear valves. A pneumatic actuator uses air pressure which is applied via a pilot valve into an actuator that raises the diaphragm to open the valve.